Commitment to Quality

At the core of our philosophy lies an unwavering commitment to excellence. Our vigilant Quality Assurance and Regulatory Affairs team, supported by a robust Quality Management System, guarantee that our offerings and internal operations consistently transcend global benchmarks. We uphold the strictest adherence to all medical device regulations, boasting full compliance with a spectrum of certifications and product registrations. Our credentials encompass ISO 13485, Medical Device Directive, In Vitro Diagnostic Directive, BSI Kitemark, Class II medical device, ISO 9001, SMETA, and the EU and UK Cosmetics Directives. These meticulous standards underscore our dedication to delivering products and services that not only meet but exceed client and consumer expectations.

Quality Management

A robust and responsive Quality Management System (QMS) is an essential part of any business involved in the production and supply of medical grade products. Our Quality Management System is at the forefront of all aspects of our business ensuring all processes lead to consistent supply of the highest quality products and customer services, this is backed up by our ISO 13485:2016 certification.

Certifications for condoms and personal lubricants

Medical Device Regulation is complex and constantly changing, making compliance a moving target. Our Regulatory Affairs team ensure our products comply to the latest regulations and are here to advise our private label customers during the creation of their own-brand condom and lubricant ranges, to ensure all products comply with the relevant regulations for the domestic and international markets they wish to sell in to.

-

Medical Device Regulations

Condoms are classified as class IIb Medical Devices. All medical devices brought to market in the European Union and UK will soon have to comply with the Medical Device Regulation (MDR), an update from the old Medical Device Directive (MDD). Pasante and Karex have been proactively ensuring that all our products, and the products of our Private Label partners, comply to the newer, more complex MDR. We also produce our Personal Lubricants as Class IIa Medical Devices, ensuring the highest quality and safety standards.

-

CE Marking

All medical devices, including condoms and lubricants, need to carry a CE-Mark to be sold within the EU. The CE mark is a conformity regulation that must be applied to products that are covered by European Union Directives. All of our male latex condoms comply with the strict requirements set out in the ISO 4074 standard and carry a numbered CE Mark. All of our male non-latex condoms comply with the ISO 23409 standard and also carry a numbered CE Mark.

-

UKCA

Following the UK leaving the EU, Medical devices sold in the UK will no longer be covered by the CE Mark and will require a UKCA Mark after a switchover period which ends on the 31st of December 2027. Pasante Healthcare have worked closely with our suppliers to ensure all our products meet or exceed the UKCA requirements and you will start to see to see the logo on our packaging from 2024.

-

BSI Kitemark

In addition to the CE Mark, the Pasante and Adore branded latex condoms also bear the BSI Kitemark. This means that these products have undergone parallel testing & quality controls to gain this certification which is owned and operated by the British Standards Institute (BSI Group). Excludes Pasante Glow, which carries CE Mark only.

-

Country Specific Regulations & Registration

With Karex selling products to over 140 countries, we have experts in the regulatory requirements for the majority of countries around the globe. We can assist in product registration in your country/state and we will work with you to ensure the products and packaging comply to the relevant regulations for your market.

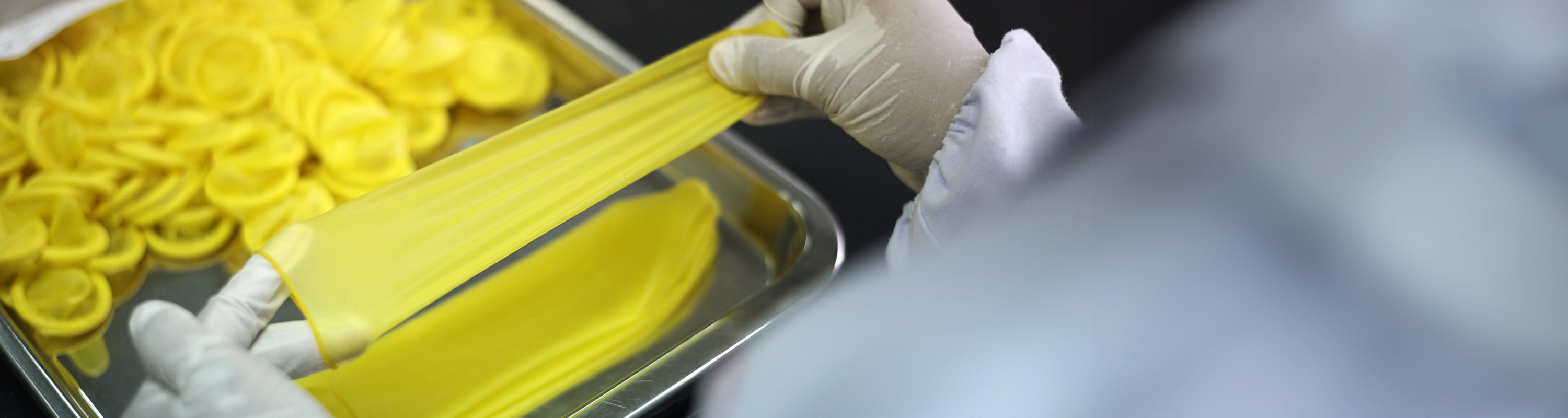

Condom Quality Testing

Every batch of condoms must undergo a strict series of electronic tests outlined below:

-

Electronically Tested

All batches of condoms are electronically tested with the results for each test systematically archived for traceability.

-

Burst Pressure Test

Condoms are inflated and must withstand a pressure way beyond anything they experience during normal use.

-

Burst Volume Test

As well as pressure, the condoms must be inflated to a specified volume.

-

Water Leakage Test

Condoms are filled with water and visually inspected for leaks.

-

Electrolyte Water Test

Electrical Test where the condom is filled with electrolyte, immersed in a bath of a different electrolyte and then tested for electrical resistance.

-

Size & Thickness Test

Condoms are measured to check they match their specification, within specified manufacturing tolerances.

-

Visual Inspection

The condoms are carefully visually inspected for any sign of defect.

-

Packaging Integrity Check

All packaging is checked for any signs of damage.

-

Packaging & Labeling Check

Packaging, labelling and barcodes are checked against the specified artwork.

Personal Lubricant Quality Testing

Every batch of personal lubricant must undergo a strict series of quality assessments outlined below:

-

Visual Inspection

A careful visual check of the product for any obvious signs of defect.

-

Packaging Integrity

The sachets, pumps or bottles are thoroughly inspected for any leaks.

-

Viscosity

The precise viscosity of the lubricant is measured, this ensures the perfect feel of the lube, from our thinner Light Lube to our thicker Lubricating Jelly.

-

Labelling Check

The labelling at all levels of the product's packaging is checked to ensure it captures all relevant information and complies with, or exceeds, the regulations of the market it is being sold into.

-

Microbe Test

All batches of lubricant must pass a test for the presence or microbes to ensure there has been no microbial contamination at any point during production.

-

Bacteria Test

All batches of lubricants must pass tests for a range of bacteria ensuring the quality and safe use of our products, whilst also ensuring a long shelf life.

-

Odour Test

The majority of Pasante Lubricants required to be odourless, with the exception of flavoured lubricants, which are assesed for the correct level of their specified flavour.

-

Clarity Check

Pasante Lubricants fully transparent and colorless, and are fully inspected for any cloudiness or discoloration.

-

pH Value

Ensuring the correct pH (acidity level) is critical for the pleasurable and safe use of products designed for use on intimate areas.